LESS PLASTIC WASTE 31/08/2021

The best ideas save the planet and the customer’s time, money and efforts. That applies to the idea two of our project managers had about reinventing the packaging of PAROC® CGL20CY insulation slabs. The story behind the project is a great example of the continuous work we do to reduce our footprint.

“Are you with me?”

This was the question project manager Mantas Strazdas from the Paroc Vilnius factory asked his Polish colleague Pawel Stempuchowski during a telephone call some six months ago.

Stempuchowski did not have to think twice. Even though the two project managers lived and worked in different countries, Stempuchowski had known Mantas Strazdas for almost 15 years. They had worked together before and Stempuchowski knew that Strazdas shared the same goals and values as him.

“Absolutely”, he replied.

So began the development of the new way of packing PAROC® CGL20CY insulation slabs and the significant reduction of plastic waste.

After the phone call, things unfolded quickly. Owens Corning Paroc has regular innovation meetings where Strazdas and Stempuchowski gave a presentation about the idea. They showed the video they had taped in Kraków and went through how they could save the customers time, effort and money and also help the environment.

The idea got a green light.

“The most critical step with any innovation is to convince yourself that the idea is good enough. If you don’t believe in it, customers won’t either”, Stempuchowski says.

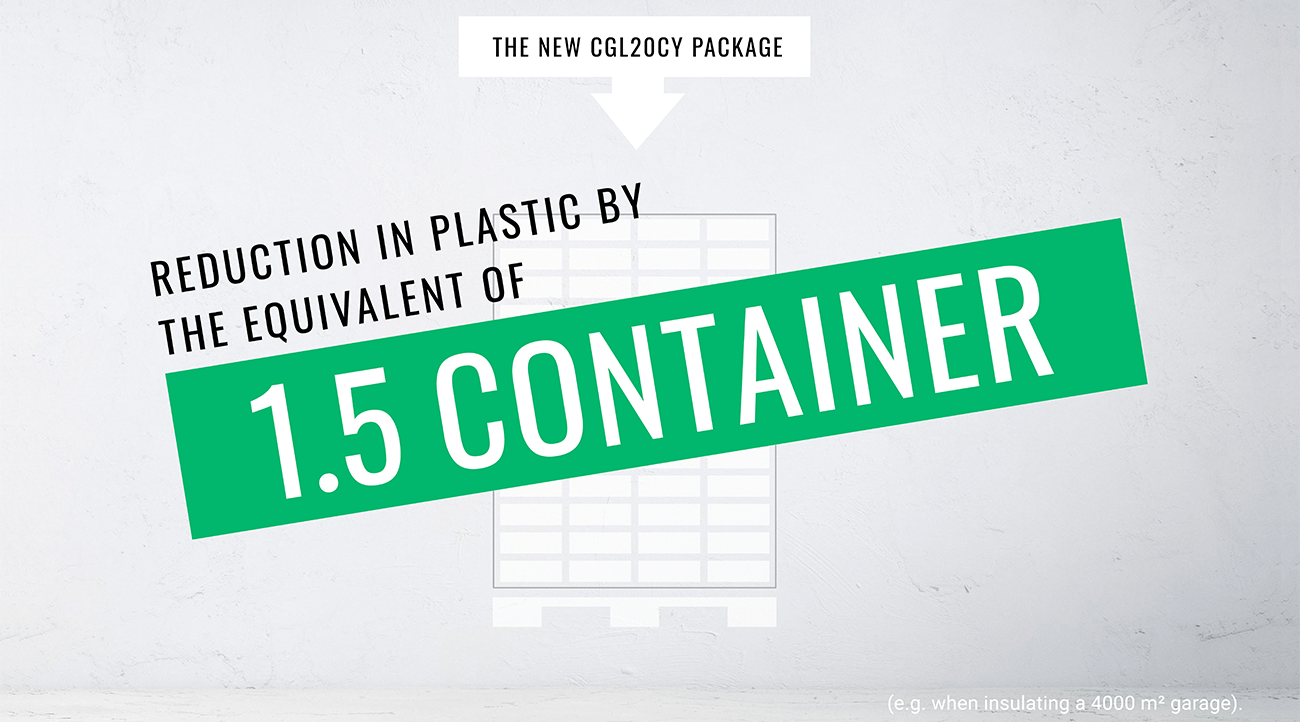

The two started to check different packing possibilities and gain insights from their colleagues in sales and product development. They ended up with a solution where PAROC® CGL20CY slabs would be packed separately onto the pallet with gluing surface upwards to speed up the installation process.

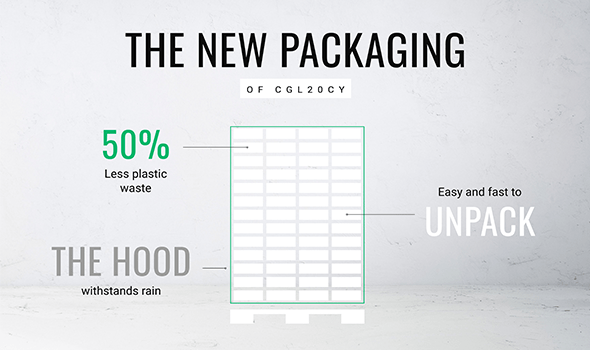

They also came up with the idea of using smaller and lower pallets that would be easier to handle in garages and cellars where the product is used. The plastic wrapped around the slabs was replaced with a hood that would have a positive impact on packing quality and offer better shelter in storage.

The only thing customers would have to unpack would be the hood.

The piloting of the new package took place in Poland. A suitable site and a customer were easy to find.

“You cannot go and ask customers that hey, we have this new product, want to test it? It is much easier, when you can say that we developed a new package that will save you time, money and create 50% less plastic waste”, Stempuchowski says.