Steam and other high temperature media are regularly processed in most industrial plants. Hence requiring a high performing thermal insulation system, in order to maintain optimal process temperatures and to prevent heat and energy losses.

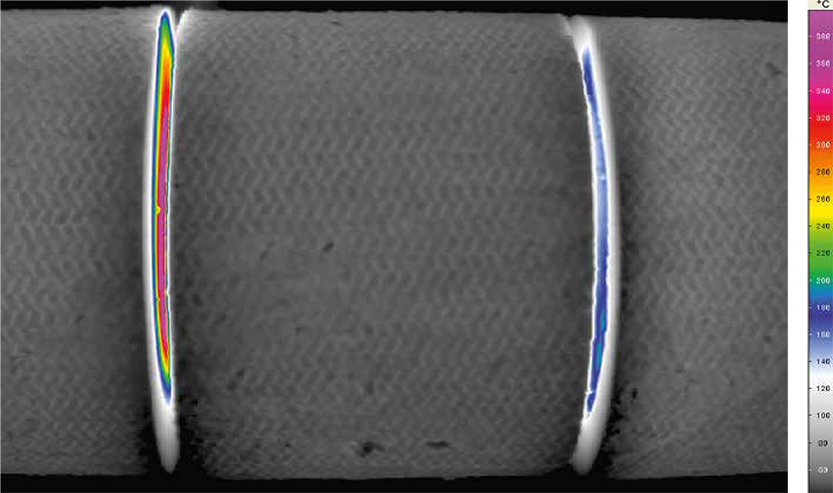

Pipe insulation systems are often installed during maintenance shutdowns. As a result, the temperature of the process pipes is similar to the ambient temperature during the installation phase.

The thermal expansion of the pipelines is handled by the z-lock formation of the joints of the PAROC Pro Lock pipe sections; that means that the performance of a double-layer solution with staggered joints is achieved with a single-layer application! PAROC Pro Lock pipe sections are available in densities 100, 120 and 140 kg/m3.

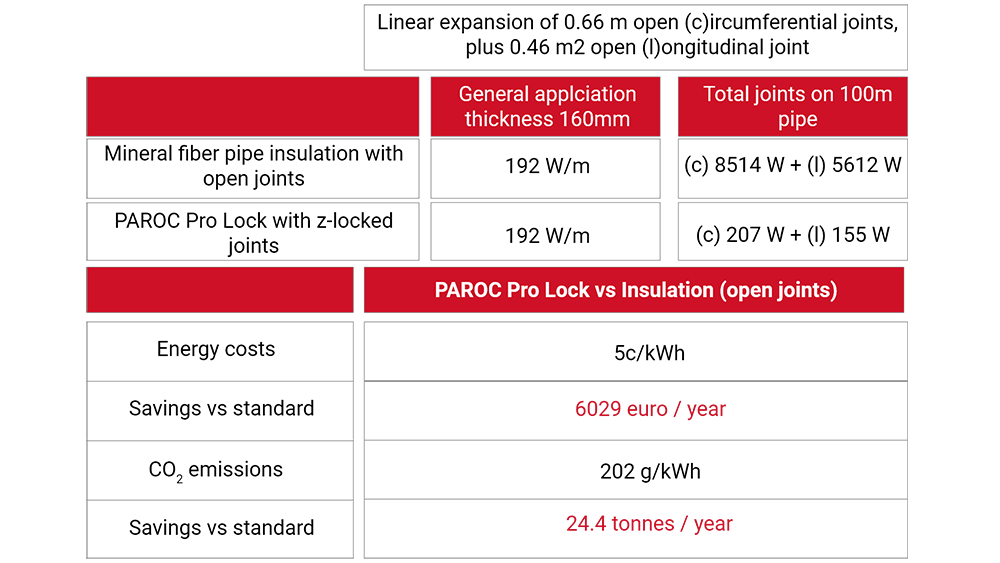

Industrial insulation specifications are often duplicated from project to project. Opportunities for reducing heat losses, reducing CO2 emissions, minimizing downtime and saving money are missed. Updating insulation specifications to include innovative solutions like PAROC Pro Lock pipe sections will offer great benefits to the process owner as well as the environment.